Repairs and maintenance of marine engines and its associated equipment is our prime activity. The seasoned staff of our workshop with sound technical and engineering skills are deeply committed to completing most demanding repair jobs within specified time frame. Our competency does not only cover engine repairs but also extends to handling complete overhaul and service of other vital machinery of deck and engine room. Our workshop is well equipped with all the necessary tools and machinery to carry out following works:

Maintenance, Repair and Overhaul (MRO)

- Overhaul of air and oil coolers

- Sand blasting and high pressure water blasting of heavy and intricate jobs

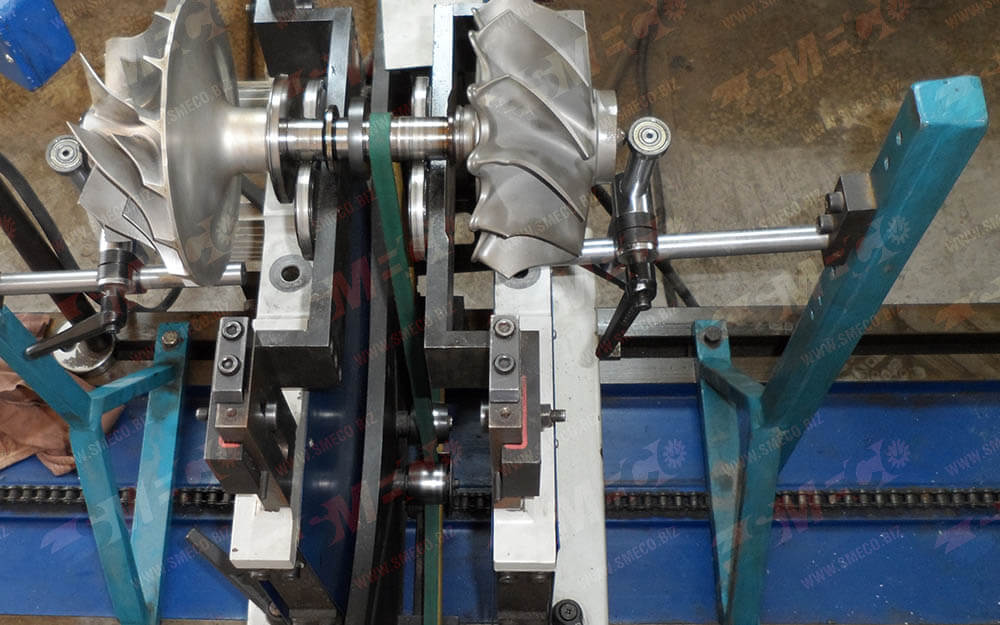

- Aux engine turbocharger service (scheduled repair + major overhaul), dynamic balancing of rotor, supply of service kit

- Deck crane boom repair, winch and gearbox overhaul, rope sheave assembly and hydraulic cylinder replacement, inspection and testing by competent person

- Repair and service electro hydraulic grabs, check power pack, replace system oil and seals, hydraulic cylinder ram rebuilt and chrome plating

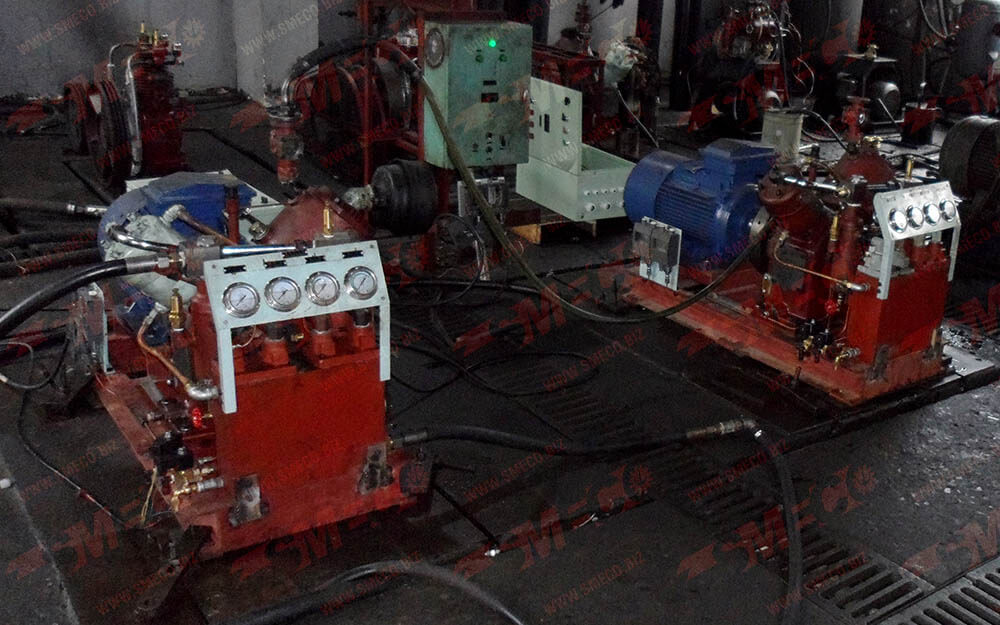

- Pump overhaul, remaking shaft, impeller balancing, casing hydrotest, replacement of worn out bush, sleeve, bearing and seals

- Decarbonisation of auxiliary engines

-

- Crankshaft grinding and spray welding

- Line boring of engine block

- Separator cleaning, parts replacement, assembly box up with fitment of balanced bowl

- Heat exchanger plate cleaning , dye penetration testing, re-gasketting

- Air compressor filter cleaning, crankcase oil change, replace drive belts, rebuilt piston, conrod machining, lapping of valve plate and valve seat

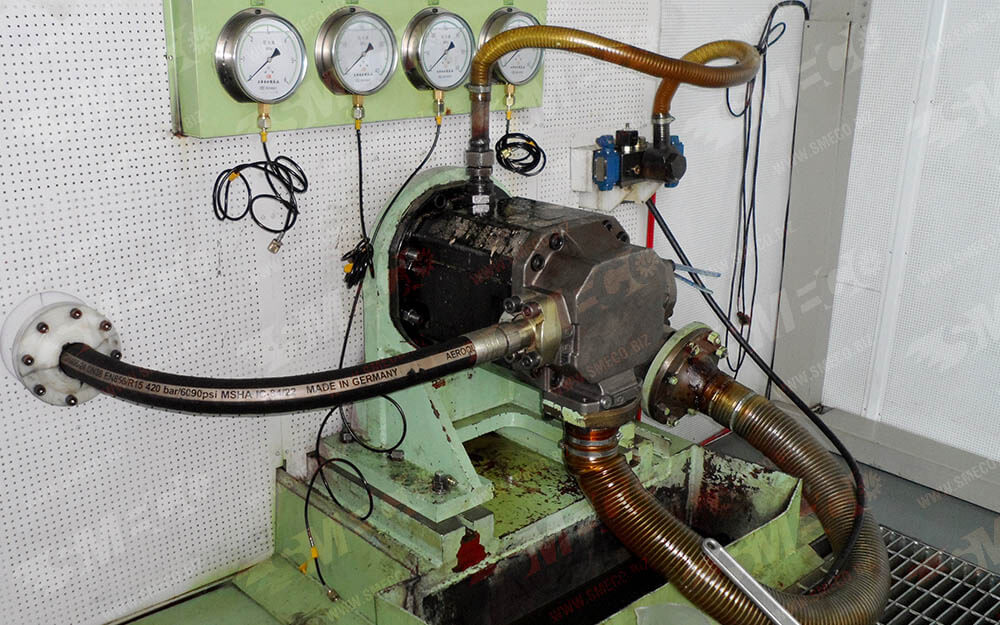

- Refrigeration compressor complete strip down, clean all parts and check tolerances as per makers recommendation, replace worn out and faulty parts using OEM spares, rebuilding crankshaft and rotor to original standard

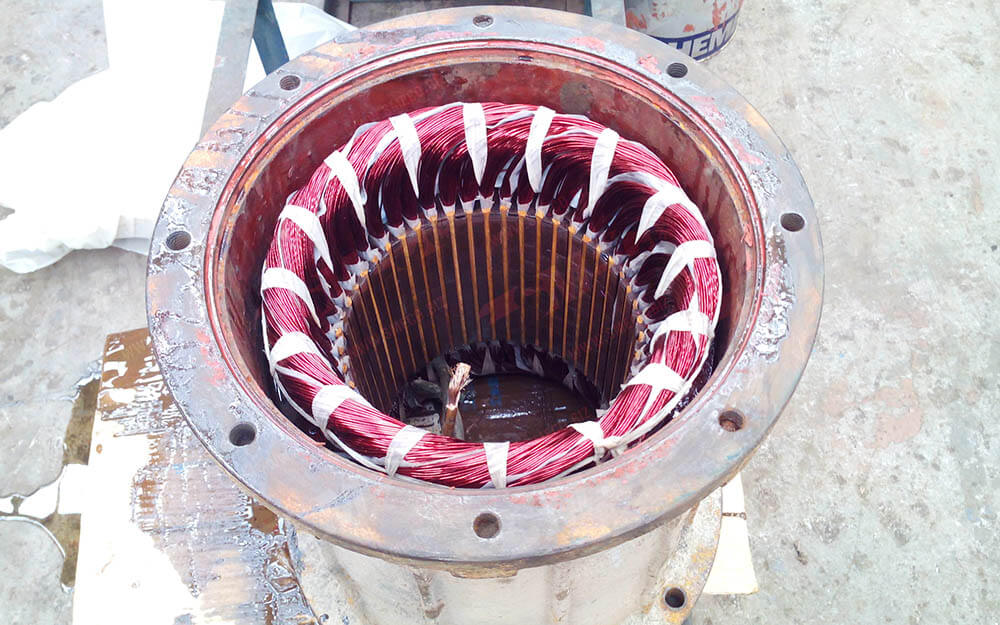

- Electric motor rewinding